Contrast performance in CPL and nylon mid-downstream

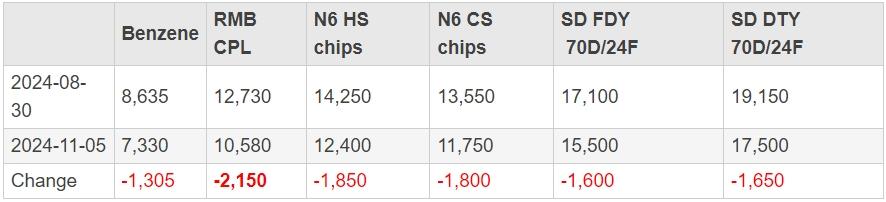

In the peak season for textile industry as a whole, the performance of nylon industry in September and October has been quite under-expected. In terms of price trend, it could be said a worst "Silver September and Gold October" ever seen in caprolactam market, with its downstream price decline accumulated by 1,500-2,000yuan/mt, and the decline in CPL sector was the largest. The prices of CPL and nylon 6 chip and filament have not just reached a year-to-date lowest, but the lowest among the past three years.

CPL prices stabilize since end-Oct

We have discussed the reason for extensive decline in CPL market . Since the end of October, the continuous decline in CPL RMB spot has seen a suspension, as CPL suppliers have suffered low processing margin for a long term, and there were a number of plant shutdowns in end-Oct. Supply of CPL had moderately reduced, and at the same time, the demand was being in its peak season, with polymer plants running at high capacity, and end user's market in healthy status.

On supply side, the sudden reduction in CPL plant operating rate from 94% to 88% in the end of October is mostly based on certain objective factors, such as maintenance of hydrogen production facilities or boilers, or due to environmental pressures. It is worth noting that from a purely market perspective, moderate production cuts are beginning to demonstrate economic viability.

| Company | Capacity (kt/year) | Operation status |

| Shenma | 200 | Shut in mid-Oct for one week, cut production in end-Oct again |

| Eversun Technology | 300 | Shut in mid-Oct till end-Oct |

| Hunan Petrochemical | 600 | Cut production to 80% during Oct 14-25 |

| Baling Hengyi | 450 | Cut production to 90% during Oct 14-31 |

| Lanhua Sci-Tech | 140 | Shut shortly in mid-Oct, shut in end-Oct again |

| Yangmei | 100 | Shut shortly in end-Oct |

| Nanjing Fibrant | 400 | Shut shortly in end-Oct |

| Lunan Chemical | 400 | Cut production to 85% in late Oct |

| Luxi Chemical | 300 | Cut production to 70% since Oct 28 |

| Hunan Petrochemical | 600 | Cut production to 80% in end-Oct |

Due to the sustained low processing fees, and more importantly, the high raw material cost for earlier inventory, the actual loss pressure for CPL suppliers now is much greater than anticipated. In the face of confirmed losses, the previous strategy of maximizing output to dilute costs is beginning to change.

Another significant reason is that the price of cyclohexanone remains relatively firm, making external procurement of cyclohexanone noticeably less profitable. This has led many factories to first reduce production of the portion that relies on externally sourced cyclohexanone, or to cut back on CPL production in order to increase the quantity of cyclohexanone sold externally.

The direct result of the production cuts is that the absolute price of CPL has begun to stabilize. The cuts have initially boosted market confidence. From the trading situation of CPL in the beginning of November, it appears that the previous inventory crisis is gradually being resolved, alleviating the selling pressure on suppliers. Although benzene listing price has dropped first, the decline in CPL has not been as significant. With the gradual ramp-up of downstream production, it is expected that CPL inventory conditions will further improve in the coming weeks, creating opportunities for price recovery.

Downstream demand growth drastic in history

In stark contrast to the CPL market, there is an extraordinary growth in downstream demand in 2024. Based on the data from January to October 2024 and estimates for the last two months, the production of CPL and PA6 is expected to grow by nearly 25% in 2024, marking the highest growth rate in the past decade. Since both CPL and PA6 are currently in net exports, the production growth rate closely aligns with the actual demand growth rate.

When looking at the year-on-year monthly comparisons, the figures are even more astounding. The production of PA6 from September to October 2024 is expected to increase by nearly 28%, and it is predicted that the year-on-year growth rate for PA6 production in the fourth quarter will reach 35-40%. Such a growth rate is remarkable within both the fiber and engineering plastics industries.

This means that in a year of the most exaggerated demand growth, CPL factories are facing the toughest challenges.

Benefiting from low raw material prices, nylon downstream sector is experiencing high growth and high profits. Several listed companies in the downstream sector reported outstanding financial results for the third quarter.

The benefiting downstream companies are embarking on a new round of expansions without delay. From November 2024 until the end of 2025, PA6 will expand its capacity by 1.5 million tons, and nylon filament yarn will also see the production of an additional 1.5 million tons. Starting from this fourth quarter, the upstream and downstream dynamics are expected to be reshaped, and the market may welcome a turning point.

- Top keywords

- Cotton Price

- Cotton Futures Price

- Cotton Futures

- CZCE

- PTA Futures Price

- Chemical Fiber

- Polyester Prices

- Wool price

- PTA Futures

- Shengze Silk

- China

- Yarn Price

- price

- China Textile City

- Fibre Price

- Benzene Price

- Cotton

- Index

- Cotton Index

- PTA

- fabric price

- NYMEX

- Top 10

- textile industry

- Spot Cotton

- Cotton Yarn

- Polyester Price

- Futures

- PTA Price

- cotton yarn price